Environmental catalyst

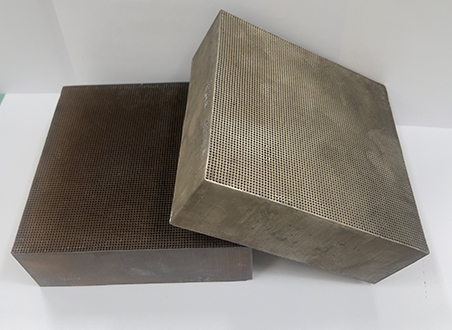

Environmental Catalyst (Highly Heat-Resistant Catalyst, VOC Catalyst)

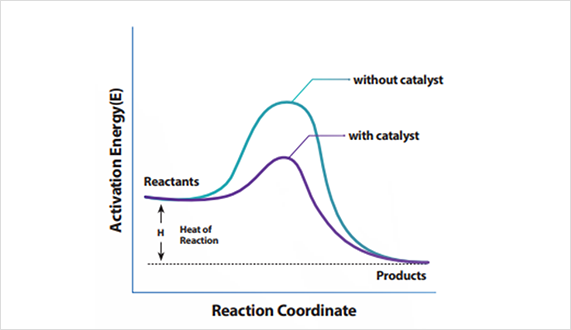

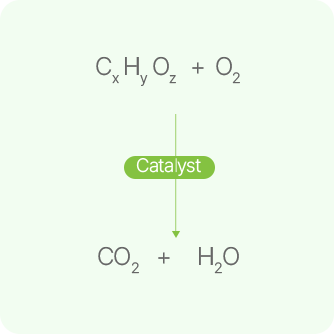

Principle & Advantage

- Materials that oxidize on-site VOCs at lower temperatures by reducing activation energies

Substances Treated

Substances

Oxidation Temperature

(˚C)

(˚C)

Catalytic oxidation

Temperature

(˚C)

(˚C)

Catalyst Complete

Oxidation Temperature

(˚C)

(˚C)

Styrene

-

-

280

(Experimental value)

(Experimental value)

Toluene

552

160

240

Acetone

650

130

250

Methanol

464

120

150

Xylene

343

150

250

Phenol

700

180

330

Butanol

343

150

250

MEK

516

145

300

Acetic Acid

-

170

320

MIBK

427

217

300

Ammonia

651

210

240

Application Table

Industry

Automotive & Steel

Semiconductor & Display

Petrochemicals & Refining

Printing

Chemicals (Chemicals, Reagents)

Tires & Tire Cord

Plywood & Furniture

Others

Facility

Paint Booths

Cleaning and Cleanrooms

Production Processes and Storage Tanks

Printing presses and dryers

Production Processes and Storage Tanks

Mixing and Curing Processes

Drying and bonding

Coating and Cleaning Processes

VOCs Generated

Toluene, Xylene, Alcohols, Esters

Alcohols, Ketones, Amines

Aromatic Hydrocarbons, Organic Acids, Aldehydes, Alcohols

Toluene, Xylene, Alcohols, Esters

Aromatic Hydrocarbons, Organic Acids, Aldehydes, Alcohols

Toluene, Xylene, Alcohols, Esters

Styrene, aldehydes, esters

Ketones (MEK, Cyclohexanone, MEK, Cyclohexanone)