Principle/Advantage

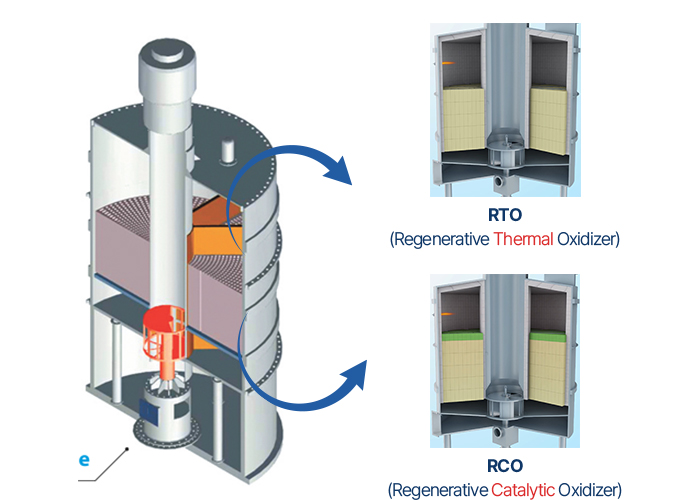

- Recovers residual heat from heat storage material by continuously changing the gas flow direction with a rotary rotor.

- Exhibits exceptional energy savings with a heat recovery rate exceeding 95%, while maintaining stable operation and eliminating pressure fluctuations.

- Features an integrated stack system that simplifies maintenance, reduces investment costs, and allows for easy inspection of heat storage materials and rotors.

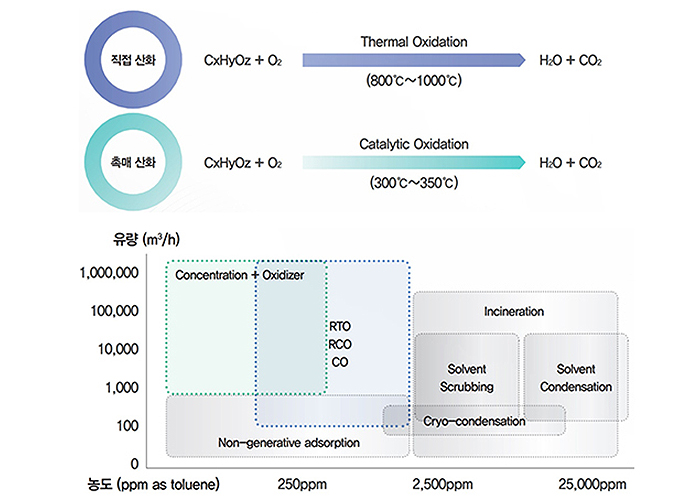

- Applicable to a wide range of VOC concentrations (100 to 2,000 ppm, based on THC) and air volumes (100 to 1,000,000 m3/h)

- Utilizes both direct and catalytic oxidation mechanisms to thermally convert VOCs and odorous substances into harmless gases.

Key References

-

RTO

(2,000 m3/min, Company "L" in Russia) -

RCO

(600 m3/min, Company "T" in Japan) -

RCO

(2,200 m3/min, Company "H" in China)

Application Table

| Industry | Facility | VOCs generated |

|---|---|---|

| Automotive & Steel | Paint Booths | Toluene, Xylene, Alcohols, Esters |

| Semiconductor & Display | Cleaning and Cleanrooms | Alcohols, Ketones, Amines |

| Petrochemicals & Refining | Production Processes and Storage Tanks | Aromatic Hydrocarbons, Organic Acids, Aldehydes, Alcohols |

| Printing | Printing Presses and Dryers | Toluene, Xylene, Alcohols, Esters |

| Chemicals (Chemicals, Reagents) | Production Processes and Storage Tanks | Aromatic Hydrocarbons, Organic Acids, Aldehydes, Alcohols |

| Tires & Tire Cord | Mixing and Curing Processes | Toluene, Xylene, Alcohols, Esters |

| Plywood & Furniture | Drying and Bonding | Styrene, aldehydes, esters |

| Others | Coating and Cleaning Processes | Ketones (MEK, Cyclohexanone, MEK, Cyclohexanone, etc.) |